COEXTRUSION AND TRI-EXTRUSION

MULTIPLE MATERIALS COME TOGETHER TO CREATE HIGHLY FUNCTIONAL PLASTIC PROFILE EXTRUSIONS.

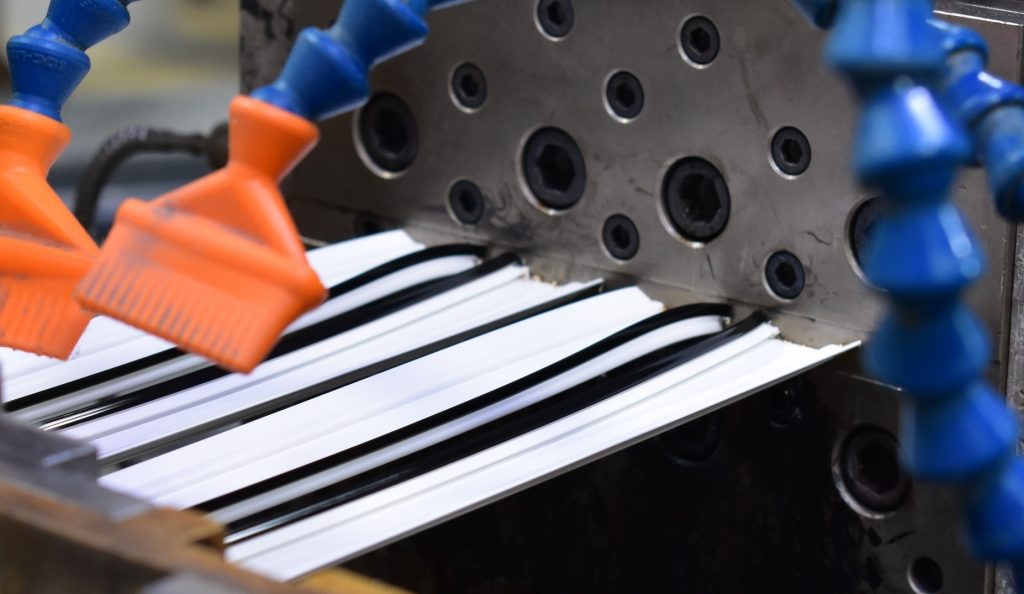

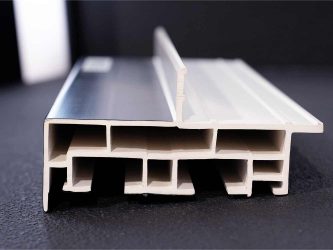

Coextrusion is one of our core capabilities. By this process, multiple types of raw material are extruded simultaneously through the same die, and fused into a single extruded profile.

Here are just a few examples of how coextrusion and tri-extrusion can be used to create a more functional product:

- Friction surfaces – Flexible plastic such as TPE or soft PVC can be used where added friction is needed, such as for gripping mating parts.

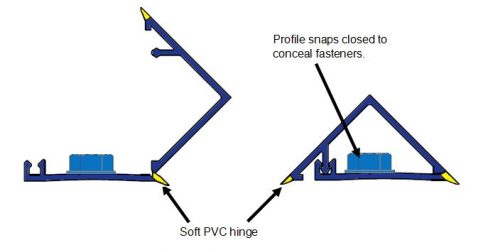

- Flexible hinges – Flexible plastic can be used between two sections of rigid plastic to create a functional hinge for parts that need to be moveable.

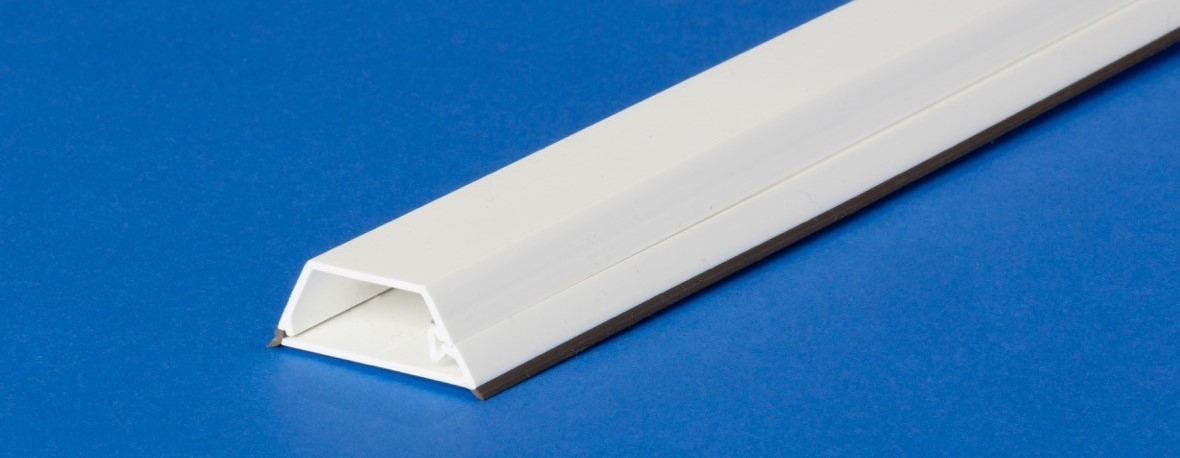

- Seals – Air seals can be created using soft plastic fins.

- High gloss finishes – A higher gloss material can be extruded over the show surface of a product to create a high-end cosmetic product.

- UV protection – If only a portion of the product will be exposed, save material cost by coextruding a UV resistant material onto a lower-cost substrate.

Contact us at (937) 236-7288 to see how our plastic extrusion technologies can help you meet your needs.

Question?

Need a quote?

Contact us:

7631 Progress Court

Huber Heights, OH 45424

Phone: (937) 236-7288

Fax (937) 236-7289